Tungsten Carbide roughing End Mill

Nā hiʻohiʻona

He mau hiʻohiʻona kaulana nā Carbide roughing end mill:

1. Hoʻolālā ʻia kēia mau wili hope e hoʻoneʻe pono i nā mea i ka wā o ka roughing, e kūpono iā lākou no ka mīkini kiʻekiʻe a me ka wehe ʻana i nā mea kaumaha.

2. Hana ʻia me ka tungsten carbide kiʻekiʻe, hāʻawi kēia mau wili hope i ka ʻoi aku ka paʻakikī a me ka paʻakikī e pale aku i nā koʻikoʻi o nā noi roughing.

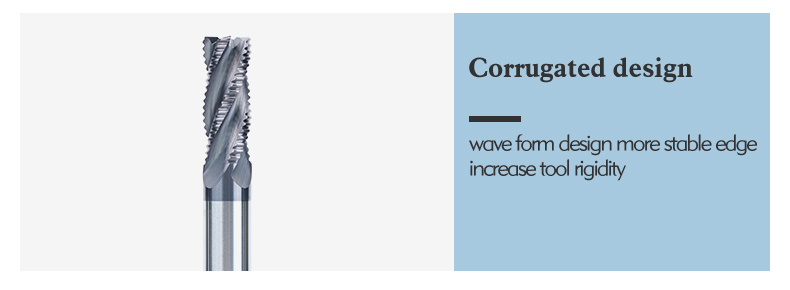

3. He ho'olālā niho ko'iko'i e ho'oma'ama'a ana i ka 'oki a me ka ho'oku'u 'ana i nā mea wili li'ili'i.

4. He kūpono no ka hana ʻana i nā ʻano mea like ʻole, me ke kila, ke kila kila, ka hao a me nā mea hao hao a me nā mea hao ʻole.

5. Hoʻolālā ʻia nā wili hope e kū i nā wela kiʻekiʻe i hana ʻia i ka wā o ka roughing, e hōʻemi ana i ka deformation thermal a me ka hōʻoia ʻana i ke ola mea hana lōʻihi.

6. Hiki ke loa'a i kekahi mau hale wili li'ili'i e like me TiCN (titanium carbonitride) a i 'ole AlTiN (aluminum titanium nitride) no ka ho'oikaika 'ana i ka pale lole a ho'olō'ihi i ka ho'ohana 'ana o ka mea hana ma lalo o nā kūlana machining pa'akikī. ola.

7. Hoʻokumuʻia nā mīkini hoʻopau e hāʻawi i ka paʻa a me ka paʻakikī i ka wā o kaʻokiʻana, e ho'ēmi i ka vibration a me ka hōʻoiaʻana i ka hana mau.

8. E hoʻonui i ka hoʻolālā ʻana o ka puʻupuʻu puʻupuʻu a me ka geometry hoʻoheheʻe chip, kahi kūpono i ka wehe ʻana i ka chip, pale i ka ʻoki hou ʻana, a hoʻomaikaʻi i ka hana pono.

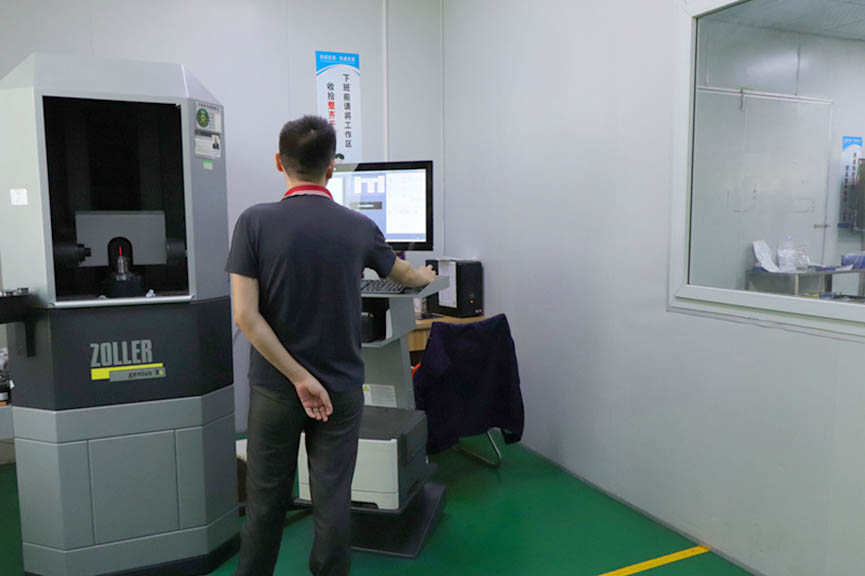

HOIKE HOIKE