Paʻa Carbide roughing End Mill

Nā hiʻohiʻona

1. Kiʻekiʻe mea kiʻekiʻe ka wehe 'ana i ka helu: Tungsten carbide roughing hope wili ua hoʻolālāʻia me ka liʻiliʻi o nā ʻohe i hoʻohālikelike ʻia me nā wili hope maʻamau. Hāʻawi kēia i ka hoʻouka ʻana i ka chip nui a me ka hana ʻoki ʻoi aku ka ikaika, e hopena i ka nui o ka lawe ʻana i nā mea. He kūpono lākou no ka wehe koke ʻana i ka nui o nā mea i loko o nā hana roughing.

2. ʻO ka paʻakikī kiʻekiʻe a me ke kū'ēʻana: Uaʻikeʻiaʻo Tungsten carbide no konaʻano paʻakikī a me ke kū'ēʻana i kaʻaʻahu. ʻO kēia ka mea e hana ai i nā wili hope loa i hana ʻia mai ka tungsten carbide me ka lōʻihi loa, ʻoiai ke hana ʻana i nā mea paʻakikī e like me ke kila kila, ke kila kila, a i ʻole ka hao.

3. Hoʻolālā niho koʻikoʻi: ʻO nā wili hope ʻokiʻoki ʻoi aku ka nui a ʻoi aku ka ākea o nā niho ʻokiʻoki i hoʻohālikelike ʻia me nā wili hope ʻē aʻe. Kōkua kēia hoʻolālā i ka hoʻokō ʻana i ka hoʻokuʻu ʻana i ka chip a pale i ka hoʻopaʻa ʻana i ka chip, e hōʻoiaʻiʻo ana i ka hana ʻoki ʻana.

4. Nā mea hoʻoheheʻe chip: Aia paha i kekahi mau hale wili pahu tungsten carbide roughing end mill i nā ʻoki ʻoki a i ʻole nā mākaʻi ʻokiʻoki. Kōkua kēia mau hiʻohiʻona e wāwahi i nā ʻāpana lōʻihi i nā ʻāpana liʻiliʻi a hiki ke mālama ʻia, e paipai ana i ka hoʻokuʻu ʻana i ka chip maikaʻi a hōʻemi i ka pōʻino o ka mea hana.

5. Kū'ē wela kiʻekiʻe: ʻO ka pale wela kiʻekiʻe o ka tungsten carbide e hiki ai i nā wili hoʻopau ʻino ke kū i ka wela i hana ʻia i ka wā o ka lawe ʻana i nā mea kaumaha. Kōkua kēia pale wela i ka pale ʻana i ka deformation o ka mea hana a i ʻole ka hāʻule ʻole ʻana o ka mea hana, e hōʻoia ana i ke ola ʻoi aku ka lōʻihi.

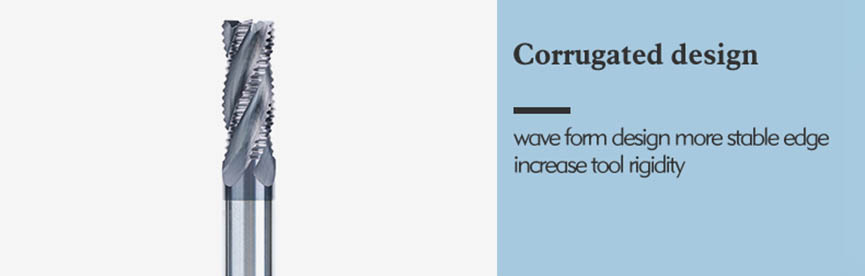

6. Helix ho'ololi a i 'ole ka ho'olālā pitch ho'ololi: Loa'a i kekahi mau hale wili hope 'ano helix ho'ololi a ho'olālā pitch ho'ololi paha ma ko lākou mau ohe. Kōkua kēia hiʻohiʻona e hōʻemi i ke kamaʻilio a me ka haʻalulu i ka wā o ka ʻoki ʻana, e hopena i ka hoʻopau ʻana i ka ʻili a hoʻonui i ka paʻa o ka mea hana.

7. Nā koho hoʻopili: Hiki ke hoʻopiliʻia nā wili hoʻopau'ōpala me nāʻano pale likeʻole, e like me TiAlN, TiCN, aiʻole AlTiN. Hoʻonui kēia mau uhi i ka hana o ka mea hana ma ka hōʻemi ʻana i ka friction, hoʻonui i ka kahe chip, a me ka hoʻomaikaʻi ʻana i ka pale ʻana. ʻO ke koho ʻana i ka uhi kūpono e pili ana i ka noi kikoʻī a me ka mea hana.

8. Hana ikaika: Hoʻokumu ʻia nā wili hope ʻo Tungsten carbide me kahi hana paʻa a paʻa hoʻi e kū i nā koi o nā hana roughing. Hoʻolālā ʻia lākou e mālama i nā ʻokiʻoki kiʻekiʻe a hāʻawi i ka paʻa i ka wā o ka lawe ʻana i nā mea kaumaha.

9. Nā koho Shank: Loaʻa nā wili wili hope ʻo Tungsten carbide me nā koho shank like ʻole, me nā shanks pololei, Weldon shanks, a i ʻole Morse taper shanks. ʻO ke koho shank e pili ana i ka mea paʻa o ka mīkini a me nā koi kikoʻī o ka hoʻonohonoho mīkini.

10. Mea hana geometries: Roughing hope mills hiki ke loaʻa i nā mea hana geometries e hoʻonui i ka hana ʻoki. Hiki i kēia mau geometries ke hoʻonui i ke anawaena kumu, hoʻoikaika ʻia nā kihi kihi, a i ʻole nā hoʻomākaukau lihi kūikawā e hoʻoikaika i ka ikaika a me ka hana i ka wā o ka hana ʻino.

Hōʻike kikoʻī

HALE HANA